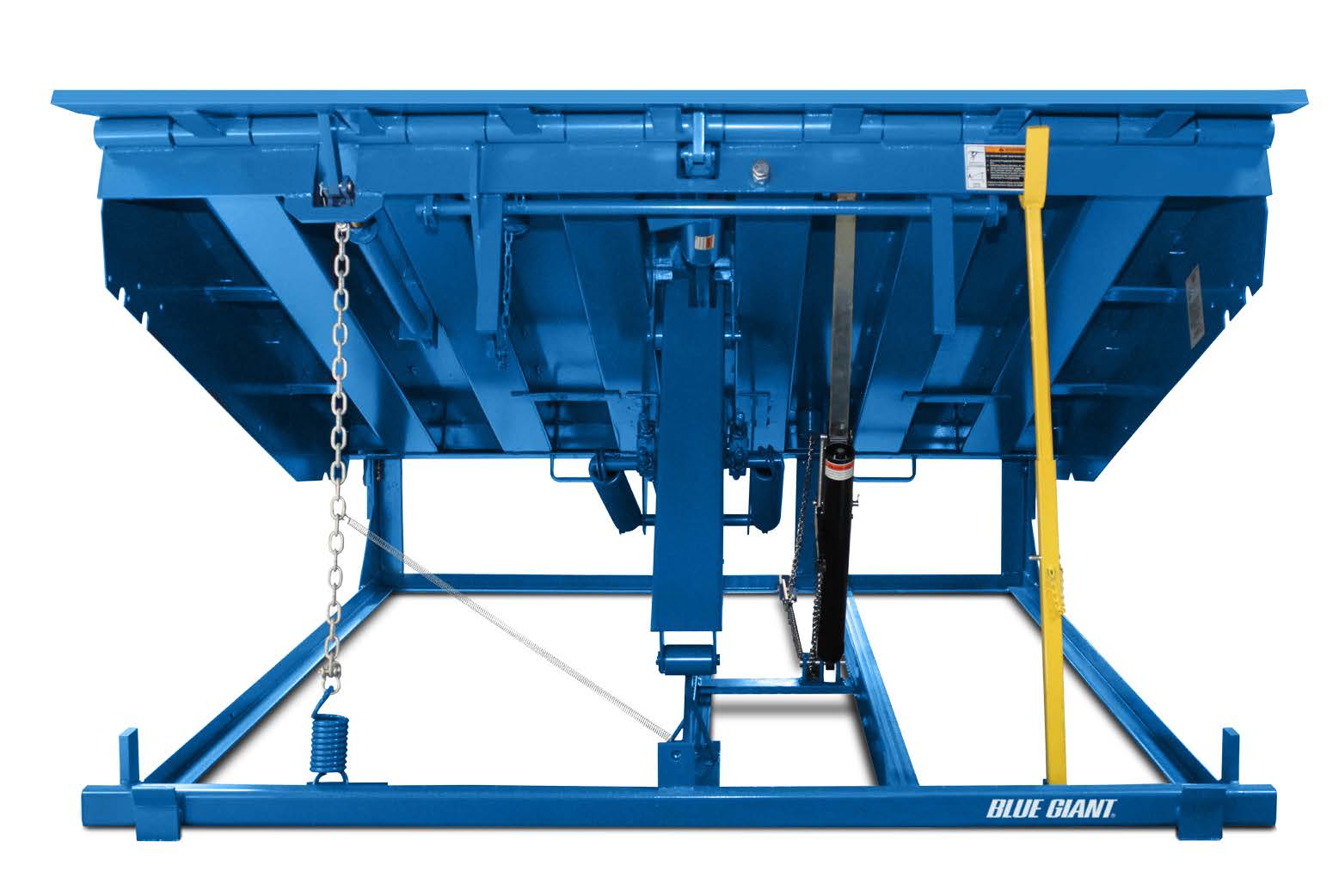

Full Frame: Strategic design provides full deck support.

Dock Strut: Supports both deck and lip for safe under-deck maintenance and inspections.

Yieldable Lip: Safely collapses if struck while extended.

Hold-down Assembly: Matches dock movement with trailer suspension.

Heavy-duty Lift Springs: Have a lifetime warranty.

Ergonomic Soft-pull Chain: Requires minimal force to deploy the deck.

Mechanical Fall-safe Legs: Limit platform free-fall.

EASY TO OPERATE

- Blue Giant mechanical dock levelers are easy to use: simply pull the release chain and let the heavy-duty main lift springs go into action.

- The deck rises up and the lip extends smoothly to the locked position. Then ‘walk’ the deck down to the truck bed and begin loading or unloading.

POWERFUL HOLD-DOWN SYSTEM

- The U-Beam features a ratchet hold-down system that offers a secure hold throughout the dock operating range, keeping it in place both during use and while parked so that safety issues such as ‘pop-ups’ are prevented.

- Automatic float compensation and pressure relief system prevents tension overload, allowing the dock leveler to seamlessly adjust to changes in trailer bed height without interrupting operation.

- Cadmium plating on the ratchet supports

- system longevity.